Tunnel construction

Shortest closure times for tunnel renovations

Of the more than 250 railroad tunnels in Switzerland, three quarters were built more than 110 years ago. On many railroad lines, the clearance gauge no longer meets today's requirements, as the new freight trains have a larger cross-section than in the past.

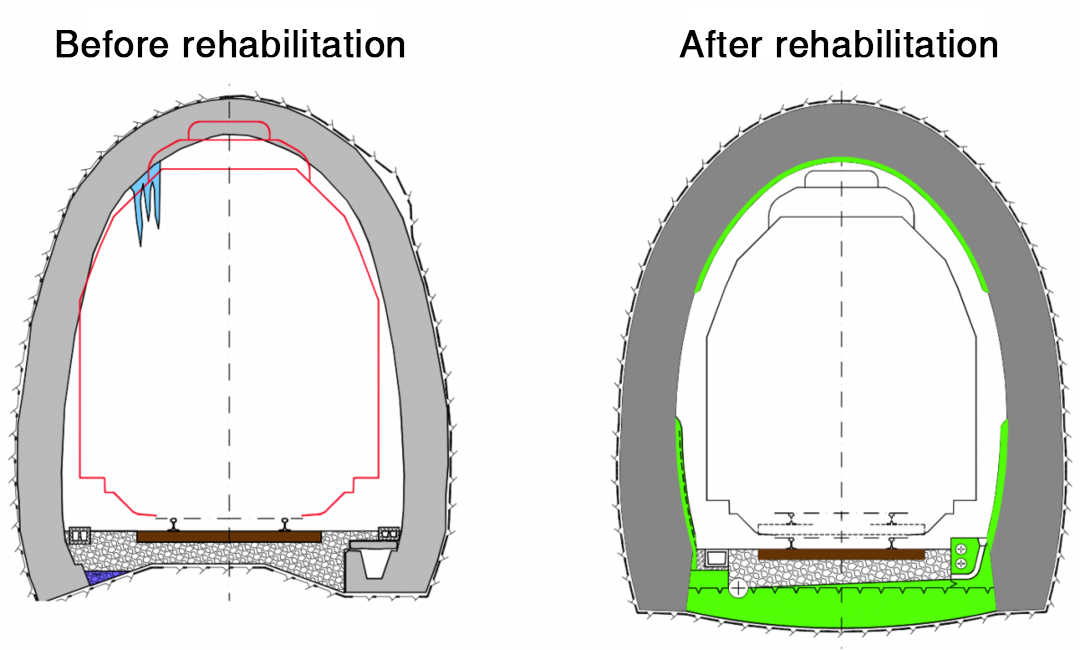

In order to widen the clearance gauge, the tunnel floor is lowered as part of a tunnel renovation, often combined with a more or less extensive vault restoration.

Previous construction methods were based on the use of auxiliary bridges. However, the auxiliary bridge construction method only allows for very slow construction progress and inevitably leads to an impairment of operations (setting up a slow-going section).

In collaboration with the leading Swiss engineering company in tunnel construction and a technical university, a new method was developed based on the use of rapid-hardening concrete. The old invert is partially or completely removed and a new invert is constructed at the lower level using rapid-hardening concrete. The old gravel roadway is often replaced by a new solid concrete roadway. Thanks to the very rapid hardening of the concrete and the simple construction process, very rapid construction progress, less disruption to operations and significant cost savings can be achieved.

Description of the construction method with rapid-hardening concrete using the example of the Herisau valley tunnel renovation

The contractor carried out the complete renewal of the road bed in just one weekend. The ambitious variant with a fiber-reinforced rapid-hardening concrete included the following work steps during a 55-hour total closure:

- Cutting and removing the tracks

- Removing the gravel

- Milling off the old concrete base using a cold milling machine

- Concreting the new base with rapid-hardening concrete

- Laying the gravel

- Laying the tracks

Thanks to the use of suitable plastic fibers, the steel reinforcement can be completely dispensed with, which further simplifies and thus accelerates the construction process.

The elaborated concept convinced everyone involved in the construction and the work was carried out on the weekend of July 16/17, 2011. The project progressed according to plan and the valley tunnel was handed back to the client just four hours before the first train journey scheduled for Monday morning. Instead of the previous three-week tunnel renovation, the repair of the valley tunnel took just one weekend and 55 hours, and operations were able to resume just in time for the start of commuter traffic.

In the meantime, this construction method for quickly widening the clearance gauge has been further refined and successfully implemented in other smaller railroad tunnels. Adapted procedures (e.g. only with night closures instead of full-day closures) based on rapid-hardening concrete technology are also ideally suited to larger tunnels and, above all, tunnels with higher traffic volumes.

Rapid-hardening concrete used: Concretum® Q-FLASH 2/20 reinforced with plastic fibers

Requirements

- C25/35, C3, XC4, XD3, XF4

- Open time of 60 min

- Consistency constant during the entire open time

- Compressive strength of > 10 MPa 30 min after start of hardening

- Consistency C3 stable and easy to compact

- No steel reinforcement required

- Can be used in the temperature range 10 - 30 °C (fresh concrete temperature)

- Low shrinkage (≤ 0.25‰) to avoid shrinkage cracks

- No cracks due to hydration heat development

Advantages of Concretum® Q-FLASH 2/20 rapid-hardening concrete

- meets all requirements of the SN EN 206-1 standard (XC4 / XD3 / XF4)

- up to 5 cubic meters per batch can be produced in the truck mixer on site on demand

- Flexible with large temperature fluctuations

- Flexible in the event of deviations from the construction program (adjustable open time)

- Can be processed like normal concrete

- Concretum specialists are on site

Downloads:

Here you will find all Safety Data Sheets, Technical Data Sheets, Product Brochures, and Project Reports.