Fast Drying of Concrete

How Fast-Drying Concrete Works

Reduce downtime and accelerate project timelines with Concretum's Q-FLASH® rapid-hardening concretes and mortars. Q-FLASH® technology achieves high strength and low moisture content within hours, enabling the application of sealants and other moisture-sensitive materials just hours after the concrete installation. This fast-drying solution minimizes disruption and maximizes efficiency for your repair and maintenance needs.

During concrete production, water is added to the cement-aggregate mix. Part of this water reacts with the cement during hardening to form cement paste, while the rest remains in liquid form within the capillary pores of the concrete. Concrete dries in different ways: part of the capillary water is bound within the cement paste, while some evaporates from the surface of the component. There are several ways to accelerate concrete drying:

1. Accelerating Hardening (more water reacts with cement in a shorter time)

2. Promoting Surface Physical Bonding

3. Increasing the Evaporation Rate

The Concretum technology for fast-drying concrete effectively leverages all three approaches. The latest generation of selected flow agents ensures optimal dispersion of cement particles. This reduces the amount of water added during concrete production (lower water/cement ratio). The proportion of capillary water that is chemically or physically bound to the surface can be increased by these high-quality flow agents. This "bound water" cannot evaporate, preventing vapor pressures that could, for example, lead to the detachment of coatings.

In the Q-products, selected rapid cements are used, which accelerate the hardening process and consume more water in less time. Concretum® C-DRY concrete also shows accelerated hardening, though not to the extent of rapid concrete. Ultimately, the sophisticated combination of suitable flow agents, adapted mix designs, and selected cements or cement compounds ensures that the drying of Concretum concretes is significantly faster compared to conventional concrete, without the need for any quick-drying additives or similar products.

Applications of Fast-Drying Concrete

Fast concrete drying is particularly required when moisture-sensitive layers or sealants need to be applied to newly created concrete surfaces, such as:

- Bridge sealings

- Industrial flooring systems

- Parking deck coatings

- Joint seals

- Etc.

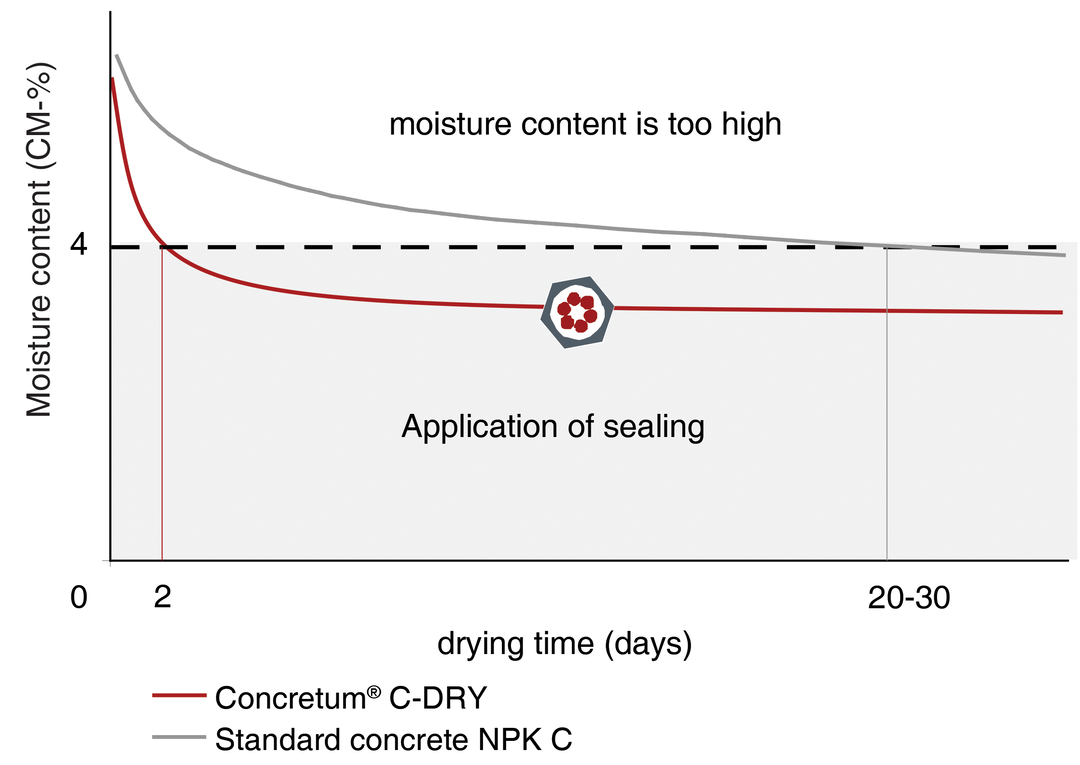

For these systems to reliably and durably adhere to the concrete, the moisture content must be below a certain threshold. For many sealants, this value is 4.0 CM-%. Concretum® C-DRY concrete reaches this value just 48 hours after production (normal concrete: about 3 to 6 weeks). With the rapid concrete Concretum® Q-FLASH 2/20, it takes only a few hours.

Measurement Method

In practice, the moisture content of concrete is usually determined using the TRAMEX® moisture meter (non-destructive). The carbide method is also acceptable.