Maintenance of air traffic areas

Rapid-hardening concrete is used wherever large concrete traffic areas need to be renewed in the shortest time possible. Especially for air traffic surfaces, where repairs can only be carried out at night.

High requirements in the maintenance of Air Traffic Surfaces

The demand on many international airports is so high today that aircraft traffic areas (runways, taxiways, stands, etc.) must be available at all times during operating hours. Therefore, repairs to these surfaces can only be carried out at night. Runways, areas with slow-moving or stationary aircraft, as well as the turning zones of taxiways, are particularly exposed to heavy loads from the increasing weight of aircraft. This results in damage (cracks, edge breaks, etc.) to the concrete slabs.

Two methods are executed in the repair process:

- Replacement of entire slabs

- Local repair of smaller areas

For the replacement of the slabs, only rapid-hardening concrete is suitable, as only a few working hours remain after the damaged slab is removed. The large field size also requires concrete with very low shrinkage and minimal heat development during hydration. The rapid-hardening concrete Concretum® Q-FLASH 2/20 was specifically developed for this application and has already been successfully used at airports worldwide many times.

For local repairs, the rapid-hardening R4 repair mortar, Concretum® Q-REP G, or Concretum® Q-CON is ideal. These cement-bound one-component mortars are mixed and applied directly on site. With this rapid-hardening mortar, a large number of defects can be repaired in a single night without issue.

Every night is different. Fluctuations in temperature, changes in weather, flight delays, or the failure of construction equipment must be responded to within minutes. In addition to reliably functioning rapid-hardening concrete, a well-coordinated team, experienced and strong construction managers, and close support from Concretum specialists are required. The special conditions, the very tight construction schedule, and the high concrete requirements place the highest demands on both materials and personnel. The handover of the repaired runway to flight operations must always occur on time, as the first aircraft typically needs to be able to land by 6:00 AM. Furthermore, the joints can already be grouted on the following night (thanks to the rapid drying).

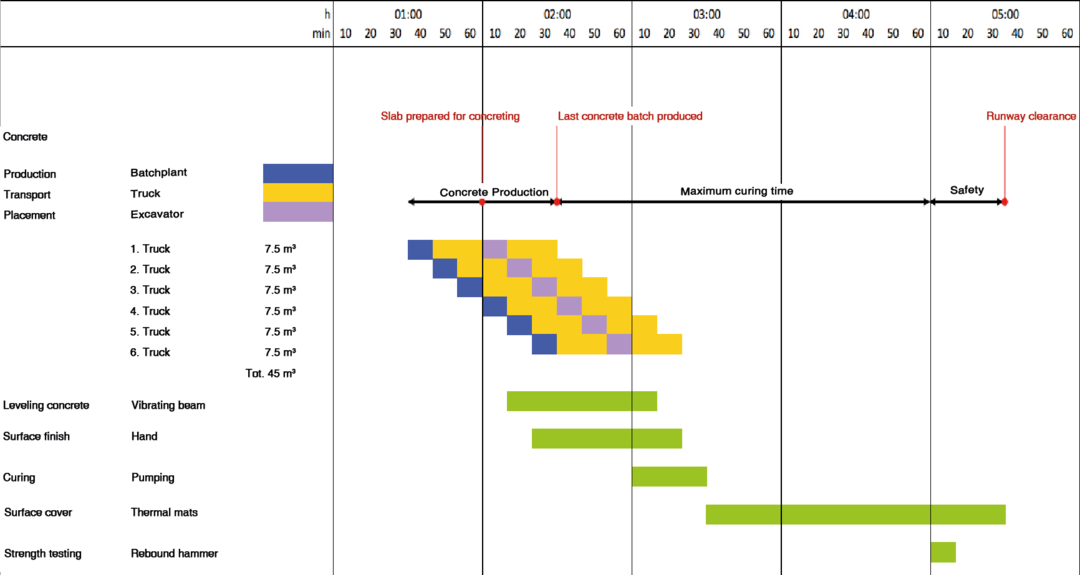

Construction Schedule for rapid-hardening Concrete (e.g. Zurich Airport)

23:30 Installation, start of demolition work, laying of reinforcement, anchoring

01:45 Start of concrete production

02:00 Start of installation

03:15 End of concrete production

04:15 End of installation, joint cutting

05:15 Strength testing, construction acceptance

05:30 Handover to flight operations

Used rapid-hardening concrete (Example: Zurich Airport)

Product Requirements

- According to standard SN EN 206: Strength class ≥ C25/35, exposure classes XC4 / XD3 / XF4

- Open time adjustable precisely between 60 to 90 minutes

- Consistency remains constant throughout the entire open time

- Compressive strength >16 MPa 60 minutes after the start of hardening

- Consistency stable, well compactable, easy to finish, broom finish

- Usable in the temperature range of 5 – 33 °C (fresh concrete temperature)

- Low shrinkage (< 0.2 ‰) to avoid shrinkage cracks

- No cracks due to heat of hydration

Advantages of Concretum® Q-FLASH 2/20 rapid-hardening concrete

- Meets all product requirements

- Large field sizes possible without crack formation

- Flexible with large temperature fluctuations

- Flexible with deviations from the construction schedule (open time adjustable)

- Crack-free with proper curing

- Processable like normal concrete

- Can be produced in a concrete plant

Used rapid-hardening Mortar (Example: Zurich Airport)

Product Requirements

- R4 Repair Mortar

- Open time of 15 minutes

- One-component system (only needs to be mixed with water)

- Compressive strength >16 MPa 60 minutes after the start of hardening

- Usable in the temperature range of 5 – 33 °C (fresh mortar temperature)

- Low shrinkage (< 0.2 ‰) to avoid shrinkage cracks

Advantages of Concretum® Q-REP G, or Q-CON

- Meets all product requirements

- Open time adjustable depending on the variant

- Various variants for different requirements (self-compacting, flowable, stable, slope-capable, etc.)

- No bonding bridge required

- Can be applied effortlessly even on damp substrates

Downloads:

Here you will find all Safety Data Sheets, Technical Data Sheets, Product Brochures, and Project Reports.