Product

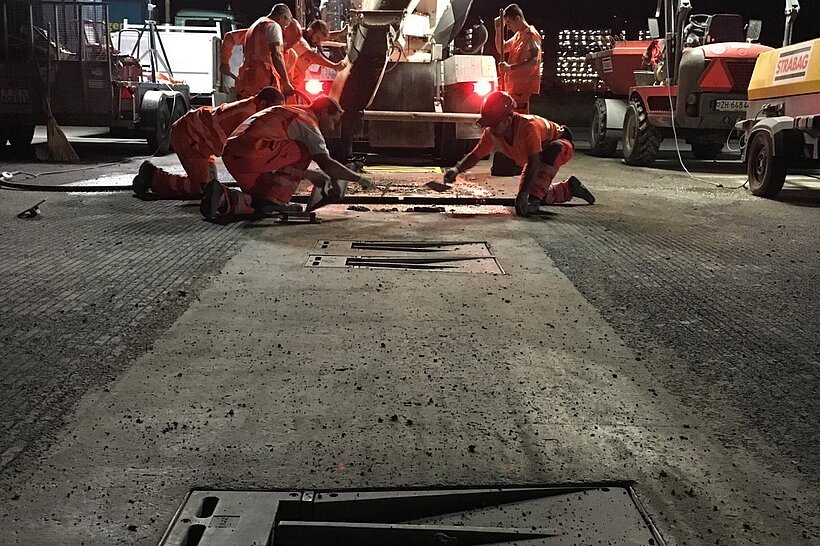

Repair of Arrestor Beams Runway 16, Zurich Airport (ZRH)

Project

The arrestor beams on Runway 16 at Zurich Airport required structural rehabilitation. In order to avoid any disruption to flight operations, the project was carried out in several night-time work phases. The concrete surface was removed using high-pressure water jetting and subsequently exposed areas were cleared using a suction excavator. The rapid-hardening concrete Concretum® Q-FLASH 2/20 was then placed and compacted. The nightly construction schedule was as follows:

| 00:00 - 01:30: | Removal of existing concrete using high-pressure water jetting |

| 01:30 - 02:30: | Suction excavator in operation |

| 02:10: | Production of rapid-hardening concrete at Ebirec plant |

| 02:30 - 03:30: | Placement of rapid-hardening concrete |

| 03:40: | Start of concrete setting process |

| 04:10: | Concrete trafficable for surface cleaning |

| 05:00: | Runway released for operations |

Special Concrete Properties

Concretum's rapid-hardening concrete was formulated to provide a working time of 90 minutes. Approximately one hour after the onset of setting, a compressive strength of >16 N/mm² was achieved. Runway release was required by 05:00.

Customer Benefit

Thanks to the use of Concretum high-performance rapid-hardening concrete, the arrestor beams could be rehabilitated without any impact on ongoing airport operations.

Facts

-

-

Country

Switzerland

-

Construction Period

2019, July

-

Client

Flughafen Zürich AG

-

Construction Company

STRABAG AG, Planer: F. Preisig AG

-

Concrete Producer

Eberhard Bau AG

-

Field of application

Air traffic areas