Product

Airport Istanbul Sabiha Gökcen (SAW)

Overnight reconstruction of runway centerline at Istanbul Sabiha Gökçen Airport

Sabiha Gökcen International Airport Istanbul was built in 2001 as a small secondary airport to Istanbul’s main airport. Originally, the airport was built with a capacity of 3.5 million passengers and a single runway. While the terminal capacity was increased to 25 million in 2008 no modifications to the runway infrastructure were performed. In recent years even, this increased terminal capacity was surpassed. With over 35 Mio. passengers Sabiha Gökcen International Airport Istanbul is the busiest airport in the world which doesn’t have a second runway in case of emergencies or maintenance. Especially on the runway the signs of overuse showed clearly. The damages range from surface dents to broken edges and completely broken concrete slabs as well as settlements of the broken fragments. In 2018 small maintenance repairs were no longer sufficient to keep the runway in operational condition and closing the runway for multiple weeks to perform a renewal wasn’t an option as this would result in the whole airport shutting down. Therefore, a different large-scale renewal method had to be found.

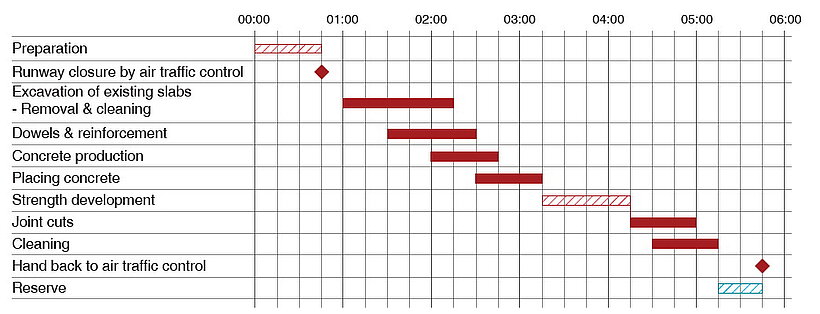

Utilizing the high early strength of Concretum® Q-FLASH 2/20 rapid-hardening concrete, it was decided to repair the damaged areas step-wise by replacing a series of broken slabs during the nightly closures at the airport lasting from 0:50 am till 5:50 am five nights a week (Monday-Tuesday, Tuesday-Wednesday, Wednesday-Thursday and Saturday-Sunday). Using the rapid-hardening concrete it was possible to reach a high early strength of over 20 MPa for the first planes to land on the freshly repaired runway each morning.

Around 90 minutes of the five-hour construction window was needed to break out the existing row of slabs and prepare the concrete pour. Afterwards the rapid-hardening concrete was poured manually and covered with thermal insulation mats until around 4.30 am when the required strength was reach. This left enough time to cut the joints and clean up the site in time for the opening of the runway. This way up to 7 slabs/ 130 m2 were replaced each night.

During the first repair season from March to September 2018 a total of 8’800 m2 of the most severely damaged areas with the highest priority were replaced over around 120 nights. These areas where mostly broken slabs in the center line regions where the planes touch down.

The following construction season an additional 7’200 m2 of slabs were replayed on the runway between April and October 2019.

Since then some additional slabs were replayed on the runway as well as on taxiways and stands during 2020 as well as 2021.

Facts

-

-

Country

Turkey

-

Construction Period

2021, April – June

-

Client

HEAS

-

Construction Company

YBT Construction and Trade

-

Concrete Producer

YBT Construction and Trade

-

Concrete Volume

10000 m3

-

Area

20000 m2

-

Speciality

Fuga Nequam

-

Field of application

Air traffic areas

-

Paving method

Manual paving